- Skin Care

- Capsule

- Food

- Ceramics, refractories & foundry materials

- Jam, Fruit, Preparation

- Gummy, Pectin Jelly, Cake

- Cosmetic and Personal Care

- Flour Products (Bread,Noodle Batter,Premix, )

- Medicine and Medical Treatment

- Ham, Sausage and Fish Processed Food

- Civil Engineering And Construction

- Paper Making

- Paper Making

- Seasonning

- Paper

- Paperboard

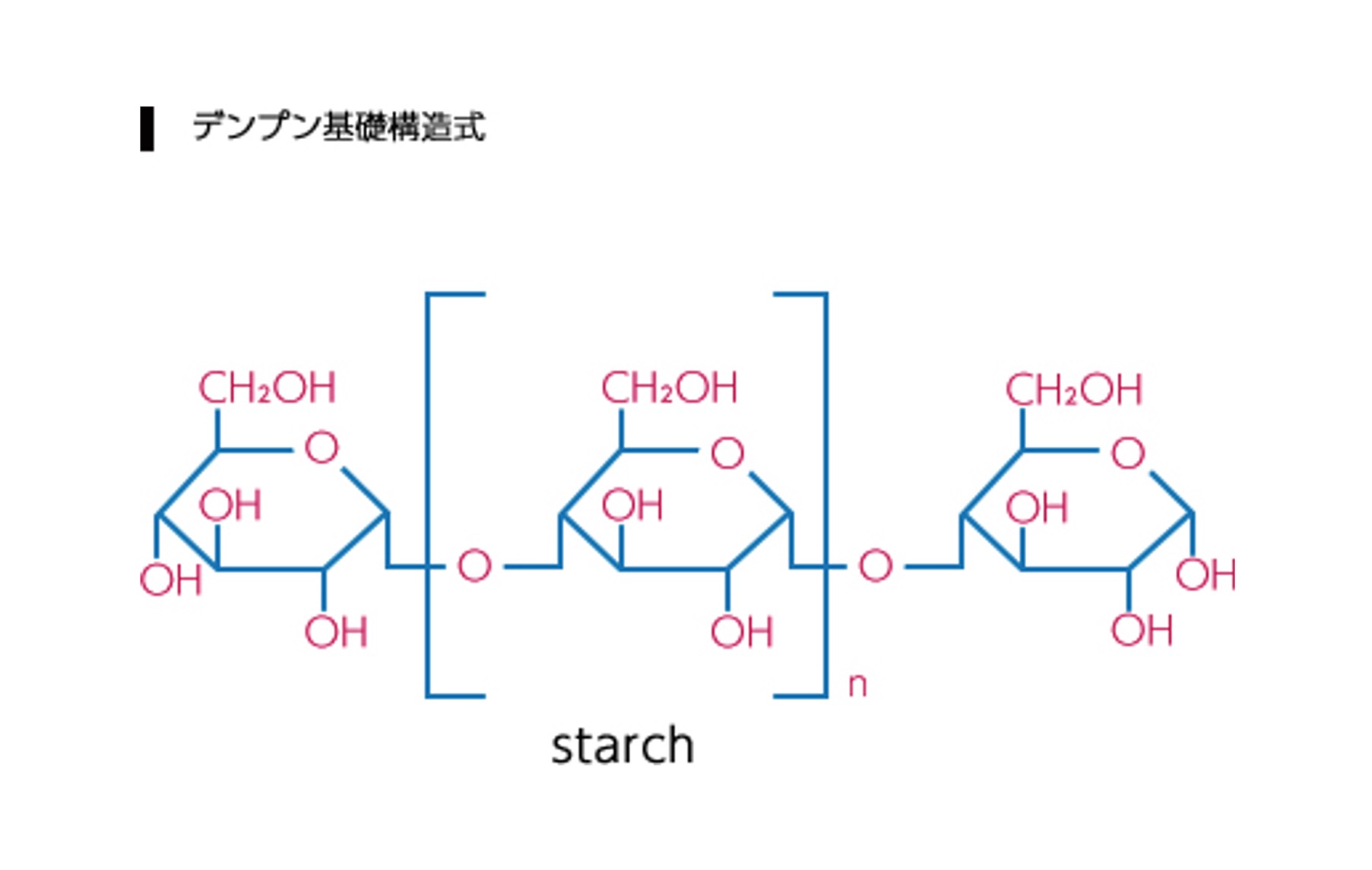

Starch

Starch is a polysaccharide and produced by photosynthesis in plant chloroplasts. It consists of numerous α-glucose units joined by glycosidic bonds. It is stocked in plant seeds, roots and underground stems widely used in food, paper, and other applications.

Starch particles are white powder and cannot dissolve in cold water. It precipitates unless it is stirred in water because its specific gravity is about 1.6. When Starch is heated in water, depending on the origin of the starch and the type of modification, it gradually expands from about 60 ℃. If it is kept heating, the particles are swelled to be broken and the solution gets high viscosity because starch molecules disperse in water.

Guar-gum derivative(industrial grade, paper grade)

Hydrolyzed guar-gum is a high-performance printing agent produced from guar-gum.

It is applied for printing with synthetic fiber.

The other guar-gum derivatives are water-soluble polymers that are modified from guar gum.

It is mainly used for enhancing of dry strength.

-

Various modifications for your application

Starch contains amylose and amylopectin. Amylose is a linear chain of α-D-glucose (It’s called ”α-1,4 bonds.”) while Amylopectin has a branch(It’s called “α1-6 bonds.”). The ratio and the degree of polymerization depend on the type of plants.

The molecular weight of amylose ranges from tens of thousands to millions while the molecular weight of amylopectin is from the tens of millions to 500 million. The difference appears the ease of retrogradation. Amylopectin is relatively stable. On the other hand, amylose has retrogradation easily. Starches are divided into “Underground starch” and “Ground starch”. Underground starch includes corn starch and wheat starch. Ground starch includes potato starch and tapioca starch. Underground starch has a less retrogradation compared with Ground starch because it has a lower amylose content than Ground one.In some cases, starch is used without any modification. But in many cases, it is modified, for example, low molecular weight, esterification, etherification, and so on.

-

-

![AIRYMO<sub>®</sub>(Fine Denier Polyolefin Chopped Fiber)]()

AIRYMO®(Fine Denier Polyolefin Chopped Fiber)

AIRYMO® is extra fine polyolefin conjug…- Paper Making

-

![FIBRIBOND®(PVA binder fiber)]()

FIBRIBOND®(PVA binder fiber)

FIBRIBOND®,registered trademark as Sansh…- Paper Making

-

![Cellulose Derivative]()

Cellulose Derivative

Cellulose Derivative are made from cell…- Cosmetic and Personal Care

- Medicine and Medical Treatment

- For Industrial Applications (Cleaner, Coating, Agrochemical,…)

- Civil Engineering And Construction

- Paper Making

-

![Guar-gum derivative(industrial grade, paper grade)]()

Guar-gum derivative(industrial grade, paper grade)

Hydrolyzed guar-gum is a high-performanc…- For Industrial Applications (Cleaner, Coating, Agrochemical,…)

- Civil Engineering And Construction

- Paper Making

-

![Vinylon fiber (PVA fiber)]()

Vinylon fiber (PVA fiber)

Vinylon fiber is a synthetic fiber made …- Paper Making

-

![Polyester fiber]()

Polyester fiber

We handle polyester fibers and their con…- Paper Making

-

![Polyolefin fiber]()

Polyolefin fiber

We handle polyolefin fibers produced by …- Paper Making

-

![Special fibers / chemicals]()

Special fibers / chemicals

We handle various functional fibers suc…- Paper Making

-

![Guar-gum and CMC for feed]()

Guar-gum and CMC for feed

Essential ingredients for aqua feed.W…- For Industrial Applications (Cleaner, Coating, Agrochemical,…)

- Civil Engineering And Construction

- Feed

-

![Biogum]()

Biogum

Biogum is a natural high-molecular weig…- Cosmetic and Personal Care

- Medicine and Medical Treatment

- For Industrial Applications (Cleaner, Coating, Agrochemical,…)

- Civil Engineering And Construction

-

![Biodegradable fiber]()

Biodegradable fiber

Biodegradable fiber is a fiber which is…- Paper Making

-

![Cationic guar gum]()

Cationic guar gum

Cationic guar gum is made from guar gum,…- Cosmetic and Personal Care

- For Industrial Applications (Cleaner, Coating, Agrochemical,…)

-